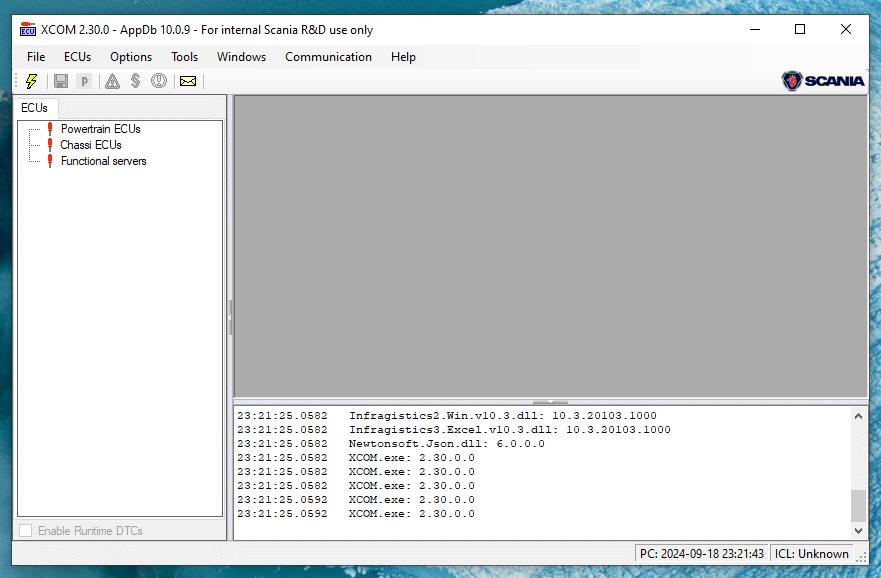

SCANIA XCOM DATABASE 10 [2024.01]

$ 130.00

SCANIA XCOM DATABASE 10 2024 is an advanced diagnostic tool designed for heavy vehicles. It enhances maintenance and troubleshooting processes by providing detailed insights into vehicle performance and fault codes. This software offers features such as real-time monitoring and optimization of engine parameters.

SCANIA XCOM DATABASE 10 2024: Revolutionize Your Heavy Vehicle Diagnostics

SCANIA XCOM DATABASE 10 2024 is an advanced diagnostic tool designed for heavy vehicles. It enhances maintenance and troubleshooting processes by providing detailed insights into vehicle performance and fault codes. This software offers features such as real-time monitoring and optimization of engine parameters. It ensures compatibility with various operating systems and hardware, making it an essential resource for technicians and fleet managers.

SCANIA XCOM DATABASE 10 2024 Overview

The SCANIA XCOM DATABASE 10 2024 represents a significant advancement in vehicle diagnostics. This comprehensive tool empowers technicians with cutting-edge capabilities to optimize heavy machinery maintenance and enhance performance tracking.

Key Features

This software includes a variety of features designed to streamline the maintenance process and improve diagnostic accuracy.

Diagnostic Capabilities

- Facilitates precise identification of fault codes through in-depth scanning processes.

- Enables technicians to analyze complex vehicle systems efficiently.

Real-Time Monitoring

- Offers real-time insights into vehicle systems, allowing for proactive issue detection.

- Helps minimize operational downtime by addressing potential failures before they escalate.

Vehicle Performance Optimization

- Allows adjustments to engine settings for improving performance under various conditions.

- Supports configurations that enhance fuel efficiency, contributing to lower operational costs.

Compatibility and System Requirements

The usability of SCANIA XCOM DATABASE 10 2024 extends to various operating systems and vehicle types, ensuring broad applicability.

Supported Operating Systems

- Fully compatible with Windows 7, Windows 10, and Windows 11, specifically 64-bit versions.

- Supports both 32 and 64-bit systems, enhancing accessibility for diverse technical ecosystems.

Vehicle and Hardware Compatibility

- Designed to work seamlessly with a range of SCANIA engines including S6, S7, and S8 models.

- Compatible with SCANIA transmission systems like OPC4 and OPC5, ensuring comprehensive diagnostic capabilities.

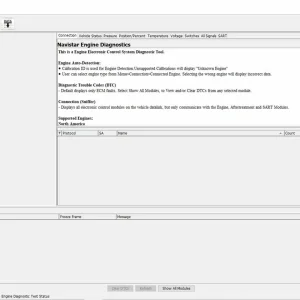

Advanced Diagnostic Functions

In the realm of heavy vehicle maintenance, advanced diagnostic functions play a crucial role in ensuring optimal performance and reliability. These capabilities allow technicians to swiftly identify and address issues, minimizing downtime and enhancing overall efficiency.

Fault Code Identification

Accurate fault code identification is essential for diagnosing vehicle issues effectively. This function enables mechanics to delve into specific problems within the engine and systems.

Comprehensive Error Code Scanning

The system is equipped with comprehensive error code scanning, allowing for an extensive review of all existing fault codes. This feature facilitates a deeper understanding of operational issues, helping technicians pinpoint exact malfunctions with precision. As codes are scanned, technicians receive a detailed report that outlines potential problems, making it easier to plan the necessary repairs.

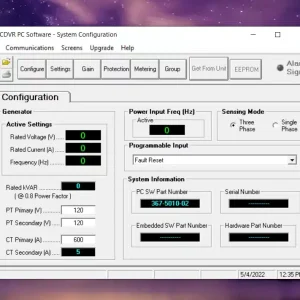

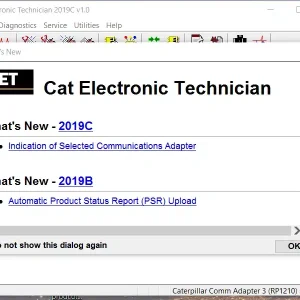

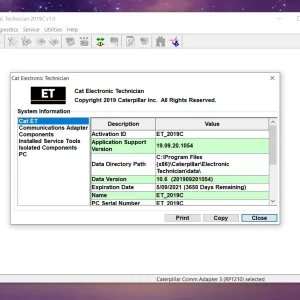

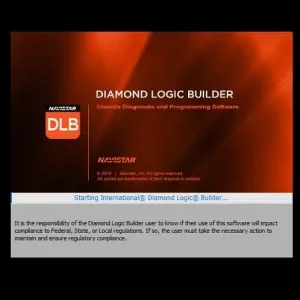

Integration with Hardware Tools

The seamless integration of SCANIA XCOM with various hardware tools enhances its diagnostic capabilities. Mechanics can connect diagnostic devices, such as scanners and adapters, to the XCOM system effortlessly. This compatibility expands the diagnostic process, enabling thorough assessments that combine hardware inspection with software analytics.

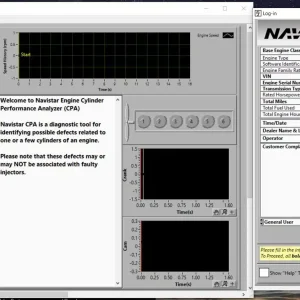

Monitoring Systems

Monitoring systems in heavy machinery are vital for ensuring ongoing performance and stability. Advance functions provide real-time insights into operational parameters.

Real-Time Data Analysis

Real-time data analysis allows technicians to monitor system performance continuously. This feature provides immediate feedback, enabling quick responses to emerging issues. By analyzing performance metrics on the fly, technicians can make informed decisions, enhancing the vehicle’s longevity and reliability.

Predictive Maintenance

Implementing predictive maintenance is another critical aspect addressed by advanced diagnostic functions. By leveraging historical data and current performance metrics, the system can forecast potential failures before they occur.

- This proactive approach significantly reduces the likelihood of unexpected breakdowns.

- It helps schedule maintenance tasks based on actual usage rather than estimates, ensuring timely interventions.

Predictive maintenance ultimately leads to cost savings and improved fleet management, allowing operators to maintain their vehicles at peak efficiency.

Vehicle Performance Optimization

Optimizing vehicle performance is essential for enhancing efficiency, reducing operational costs, and ensuring compliance with environmental regulations. Through effective adjustments and management strategies, significant improvements can be achieved in vehicle operations.

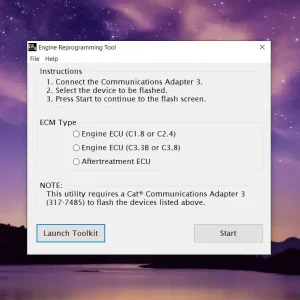

Engine Parameter Adjustments

Adjustments to engine parameters play a vital role in maximizing a vehicle’s overall performance. These adjustments can lead to better fuel efficiency and improved power output.

Customizing Engine Configurations

Tuning engine configurations involves fine-tuning various settings to match specific operating conditions. This process can optimize power delivery and improve responsiveness. Techniques include altering ignition timing, adjusting air-fuel mixtures, and modifying turbocharger settings. Each of these adjustments can significantly enhance engine performance tailored to the demands of the application.

Fuel Efficiency Improvements

Improving fuel efficiency is a primary concern for fleet operators. Effective fuel management strategies include:

- Implementing optimized fueling techniques.

- Regular maintenance of fuel injectors and filters.

- Monitoring driving habits to promote fuel-saving practices.

These practices collectively lead to reduced fuel consumption and lower operating costs while promoting a more sustainable operation.

Emissions Control Management

Managing emissions is critical for adhering to environmental laws and ensuring that vehicles operate within regulatory limits. Accurate adjustments can assure compliance and reduce a fleet’s environmental footprint.

Modifications for Compliance

To comply with emissions regulations, vehicles may require software adjustments and hardware modifications. This can involve updates to the engine control unit (ECU) settings to optimize emissions performance. Specific actions include recalibrating exhaust gas recirculation (EGR) systems and fine-tuning particulate filters for maximal efficiency.

Eco-Friendly Operations

Implementing eco-friendly measures is becoming increasingly important in the transportation industry. Several strategies can contribute to greener operations:

- Utilizing biodiesel or alternative fuels to mitigate environmental impact.

- Incorporating hybrid or electric vehicles into the fleet.

- Regularly assessing the vehicle’s emissions data to implement necessary modifications.

These practices not only help in reducing the carbon footprint but also enhance the sustainability of fleet operations moving forward.

Sé el primero en valorar “SCANIA XCOM DATABASE 10 [2024.01]” Cancelar la respuesta

Productos relacionados

All Products

All Products

All Products

Valoraciones

No hay valoraciones aún.